Resistance Heating Alloy

High-Performance Resistance Heating Alloys for Industrial & Infrared Applications

FeCrAl Alloy Heating Wire (Iron-Chromium-Aluminum Series)

Grades:

0Cr25Al5, 0Cr23Al5, 0Cr21Al6, 0Cr21Al4, 0Cr19Al3, 0Cr17Al4

Diameter: From 0.06mm to 8.23mm

Temperature Range: Up to 1,400°C continuous

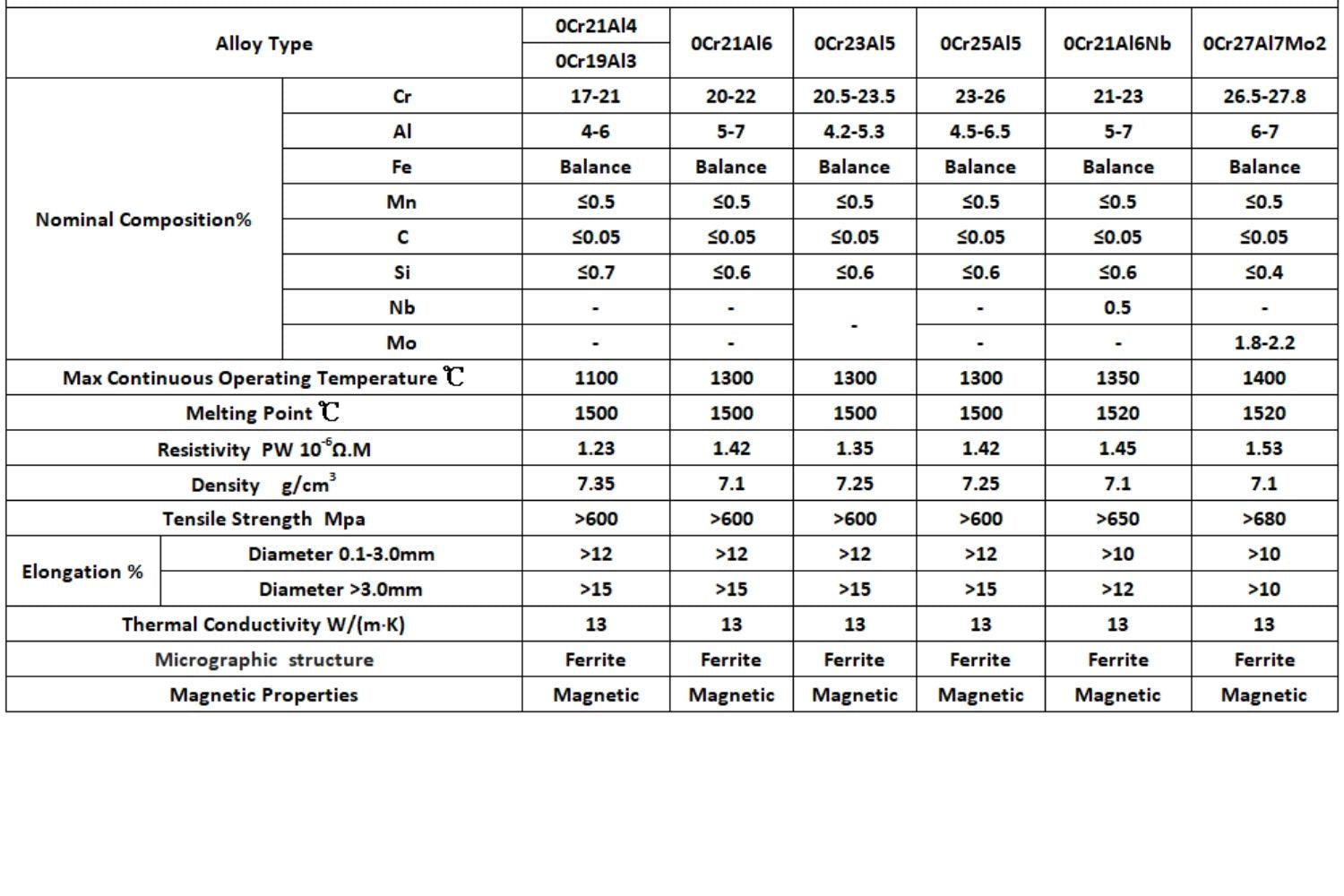

Physical and Mechanical Properties of Sundear FeCrAl Resistance Alloy wire

Key Features & Benefits

Premium FeCrAl (Iron-Chromium-Aluminum) Resistance Heating Alloy Wire – High-Temperature Performance & Oxidation Resistance

Extreme Temperature Stability

Capable of withstanding continuous operating temperatures up to 1400°C (2552°F), significantly higher than most NiCr alloys.

Excellent High-temperature Oxidation Resistance

Upon heating, FeCrAl forms a protective, self-insulating layer of aluminum oxide (Al2O3), which prevents further corrosion and extends the life of the element.

Excellent Formability

Our wire is annealed for optimal ductility, making it easy to coil and shape without compromising structural integrity.

High Electrical Resistivity

With higher resistivity than NiCr, FeCrAl allows for more compact element designs and weight savings.

Cost-Effective Durability

Free of expensive nickel, this alloy offers a more stable pricing structure while providing a longer service life in sulfur-containing atmospheres.