In the world of high-performance heating elements, insulation reliability under extreme environmental conditions is one of the most critical safety and quality indicators. At Sundear, we don’t rely on assumptions—we validate our products through rigorous environmental testing, ensuring every heating tube meets the highest global standards.

One of the key procedures in our quality system is the Low-Temperature & High-Humidity Environmental Test, designed to evaluate leakage current, electrical insulation, and overall structure stability when exposed to moisture-rich environments.

Why Test Heating Tubes in Cold & Humid Conditions?

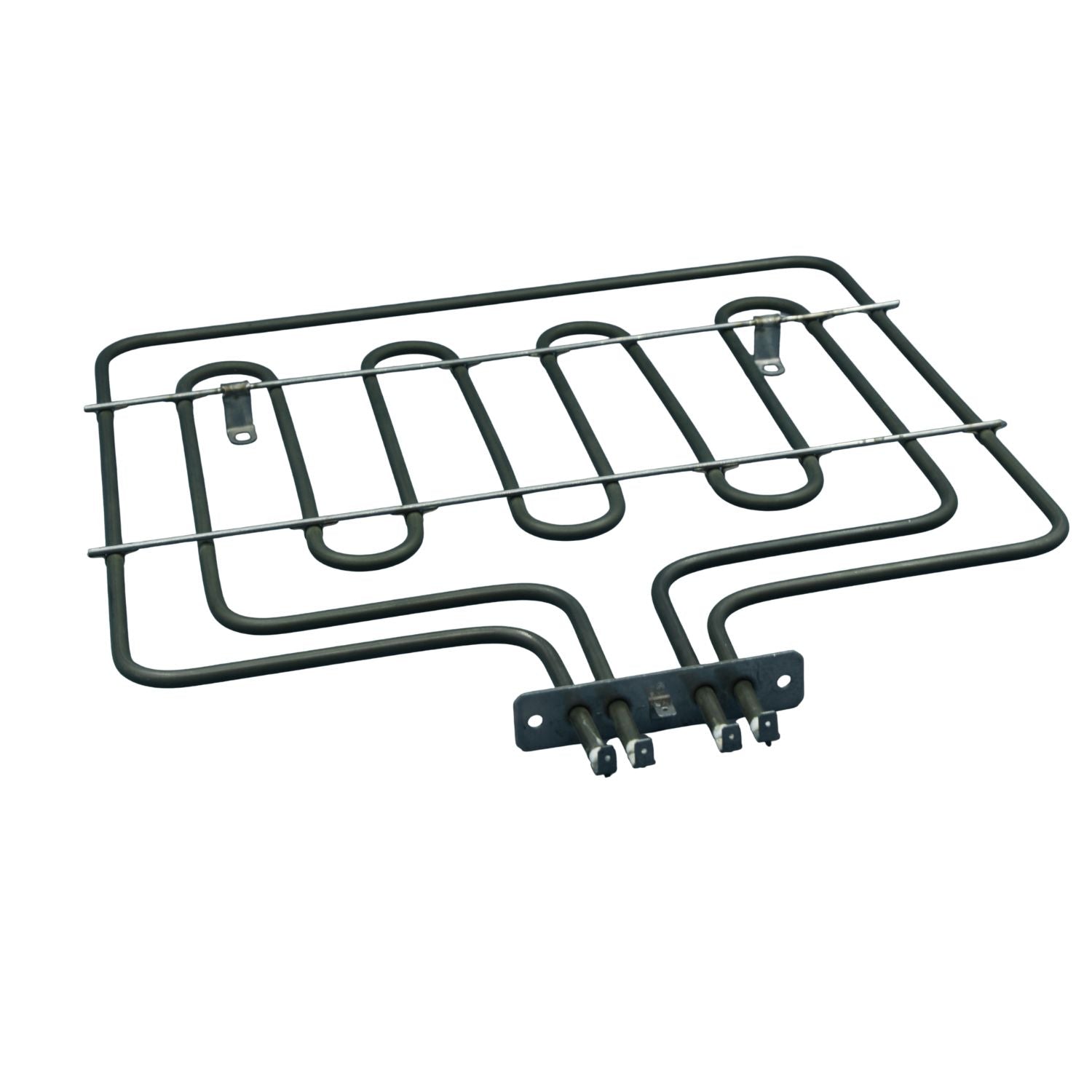

Heating elements operating in appliances such as ovens, refrigerators, water heaters, HVAC systems, or industrial machines often face:

- Rapid temperature transitions

- Condensation and humidity

- Water vapor exposure

- Freezing-to-heating cycles

These environmental changes can lead to:

- Increased leakage current

- Degraded insulation

- Short circuit risk

- Cracking of magnesium oxide (MgO)

- Corrosion or structural deformation

For premium heating elements, stable insulation resistance and zero leakage current—even after extreme environmental shocks—are mandatory.

Our Testing Protocol: Simulating Real-World Moisture Stress

Based on our internal engineering standard (Test No. 20251111-01)

巴西样品模拟冰箱测试报告-原件

Sundear performs the following steps to validate insulation safety:

1. Pre-Test Electrical Characterization

Each sample undergoes:

- High voltage withstand test

- Insulation resistance test (≥500 MΩ @ DC 500V)

- Leakage current measurement (<0.15 mA)

- Power measurement after 5-minute energizing

This establishes a stable baseline of electrical health.

2. 24-Hour Low-Temperature (Refrigeration) Exposure

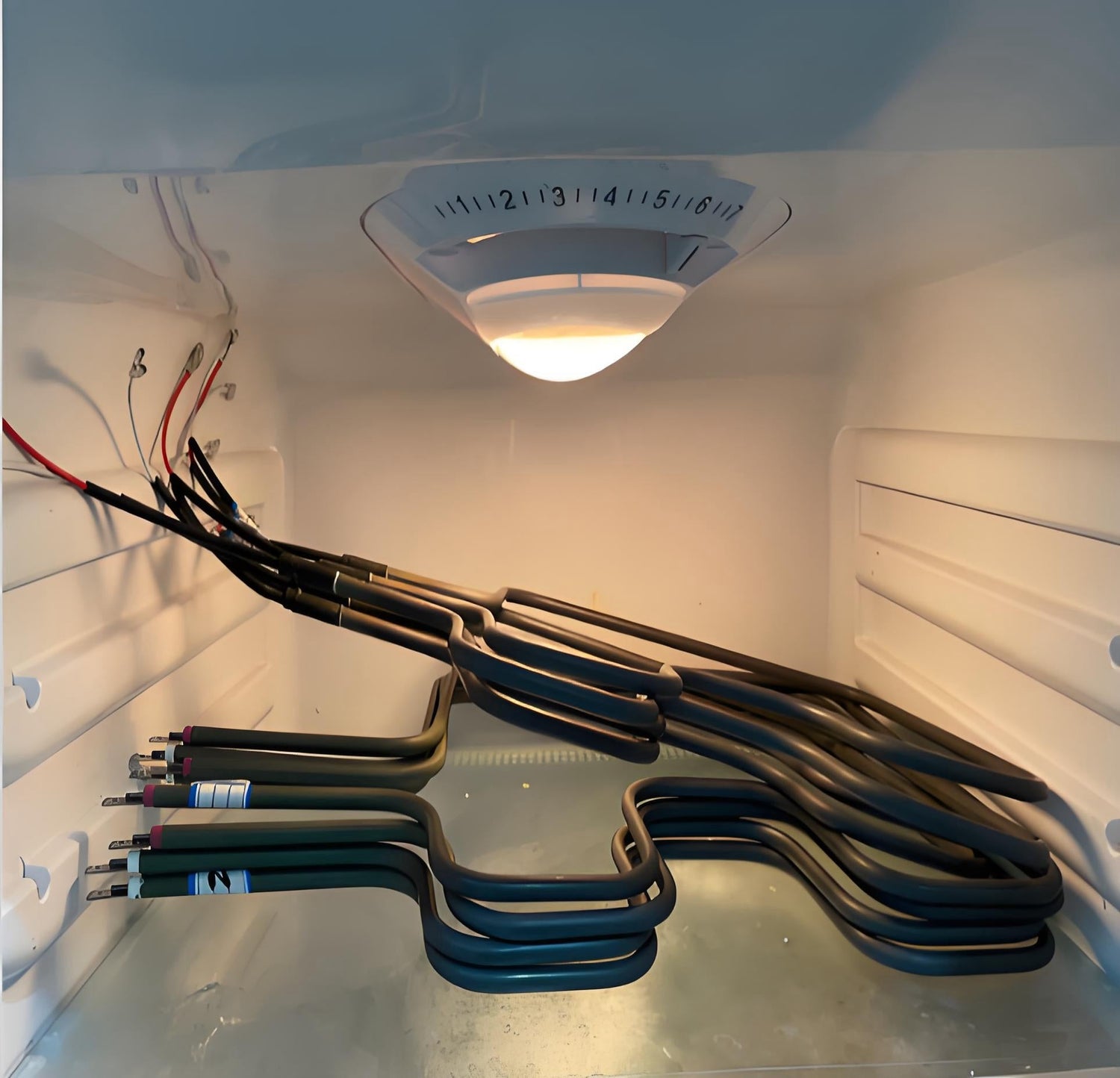

The heating tubes are energized, then placed into a refrigeration chamber for 24 hours to simulate:

- Moisture penetration

- Condensation stress

- Sudden temperature shock on MgO filling and terminal joints

This creates the worst-case scenario for insulation degradation.

3. Controlled Thawing (3 Hours at Room Temperature)

After removal, samples are rested for 3 hours at ambient temperature to observe:

- Condensation behavior

- Moisture absorption inside the tube

- Performance stabilization

- Insulation recovery capability

This phase reflects real-world appliance cycles where a heater returns from cold conditions into normal operation.

4. Final Electrical Safety Assessment

Every sample is re-tested for:

- Insulation resistance

- Withstand voltage performance

- Leakage current stability

- Structural integrity (no cracks, no deformation, no burnlling)

All Sundear samples passed with a “Qualified / PASS” result across aitems

巴西样品模拟冰箱测试报告-原件

Key Findings: Reliable Insulation Even After 24h Extreme Cold

From the test data:

- No tube showed cracking, deformation, or material failure.

- Leakage current remained extremely low (0.027–0.056 mA).

- Insulation resistance remained within safe range.

- Terminal sealing with RTV, magnetic beads, and heat-shrink structures performed reliably.

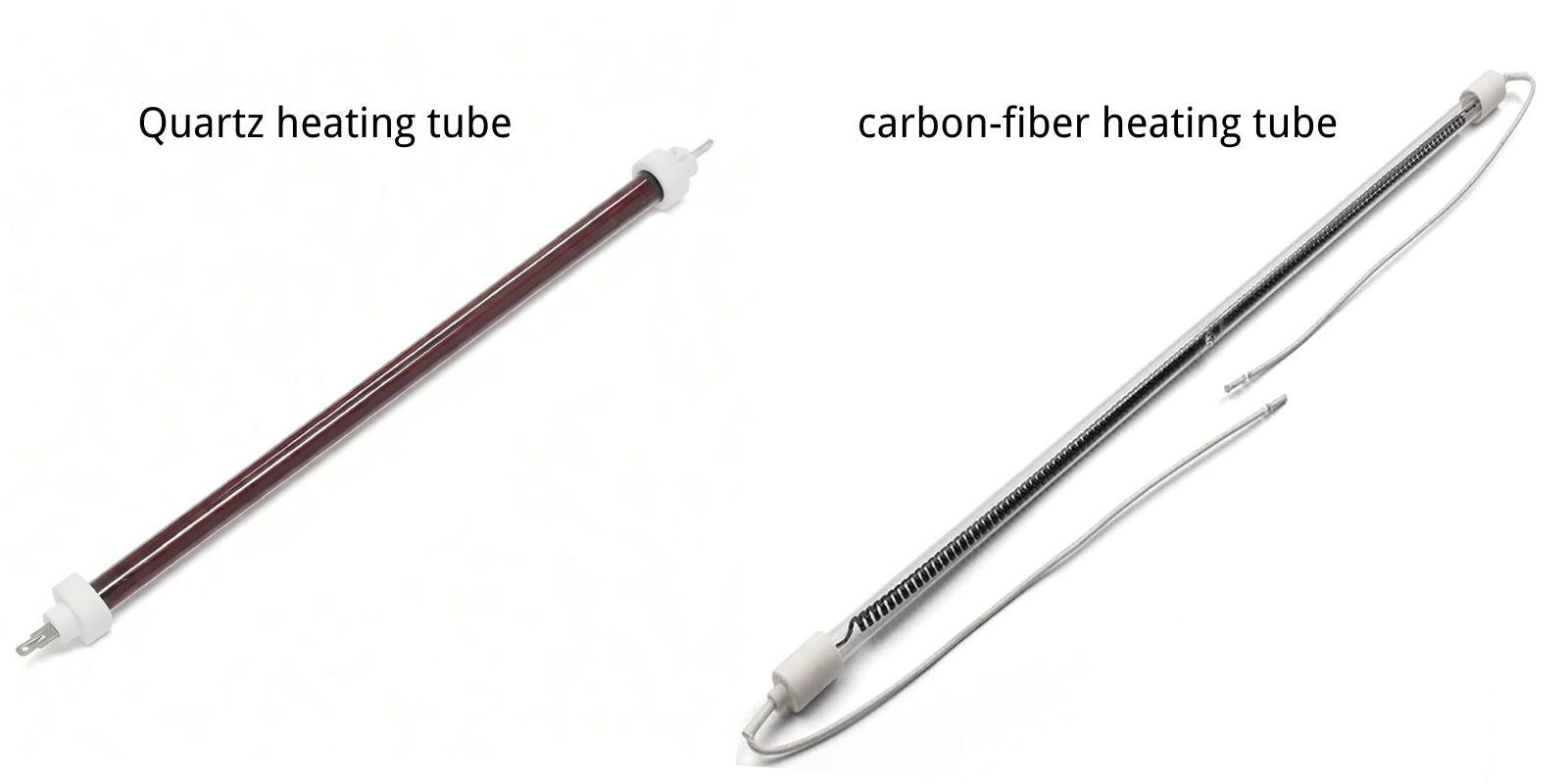

- Both OCr25Al5 and Ni80Cr20 heating wires demonstrated stable electrical performance.

These results prove that Sundear’s heating tubes maintain excellent insulation reliability even after prolonged exposure to cold, humid environments.

What This Means for Our Customers

1. Higher Safety Reliability

Our heating elements maintain insulation integrity under moisture stress—reducing risks associated with leakage current.

2. Longer Service Life

Cold-to-hot cycling is one of the toughest conditions for MgO-filled heaters. Sundear’s performance after 24 hours of condensation shock demonstrates exceptional durability.

3. Better Adaptability

Whether used in home appliances, industrial equipment, or commercial products, our heaters remain stable across a wide climate spectrum.

4. International-Grade Quality Assurance

By integrating strict in-house environmental testing, Sundear delivers a heating element that meets or exceeds expectations for global markets.

Why Sundear’s Testing Matters

For more than 30 years, Sundear has been committed to manufacturing premium heating elements built on:

- High-precision production

- Engineering-grade material selection

- Advanced sealing and insulation technology

- A complete, professional testing ecosystem

Our environmental test lab ensures every product is validated beyond basic compliance—reflecting our brand’s dedication to premium quality and long-term reliability.

Conclusion: Engineering Confidence Through Real Testing

The Low-Temperature & High-Humidity Test is one of many rigorous validation procedures we perform. By simulating real-world moisture and condensation challenges, Sundear ensures our heating elements are safe, stable, and built to last.

This commitment to quality is the foundation of our reputation as a professional heating element manufacturer and trusted global partner.