When you design or select heating elements for ovens — whether home appliances, commercial ovens or industrial cooking equipment — the choice between carbon-fiber heating tubes and quartz (infrared) heating tubes matters a lot. Each has strengths and trade-offs depending on application, performance, cost, and lifespan.

Below is a detailed comparison to help you make an informed decision.

How They Work — Basics of Each Technology

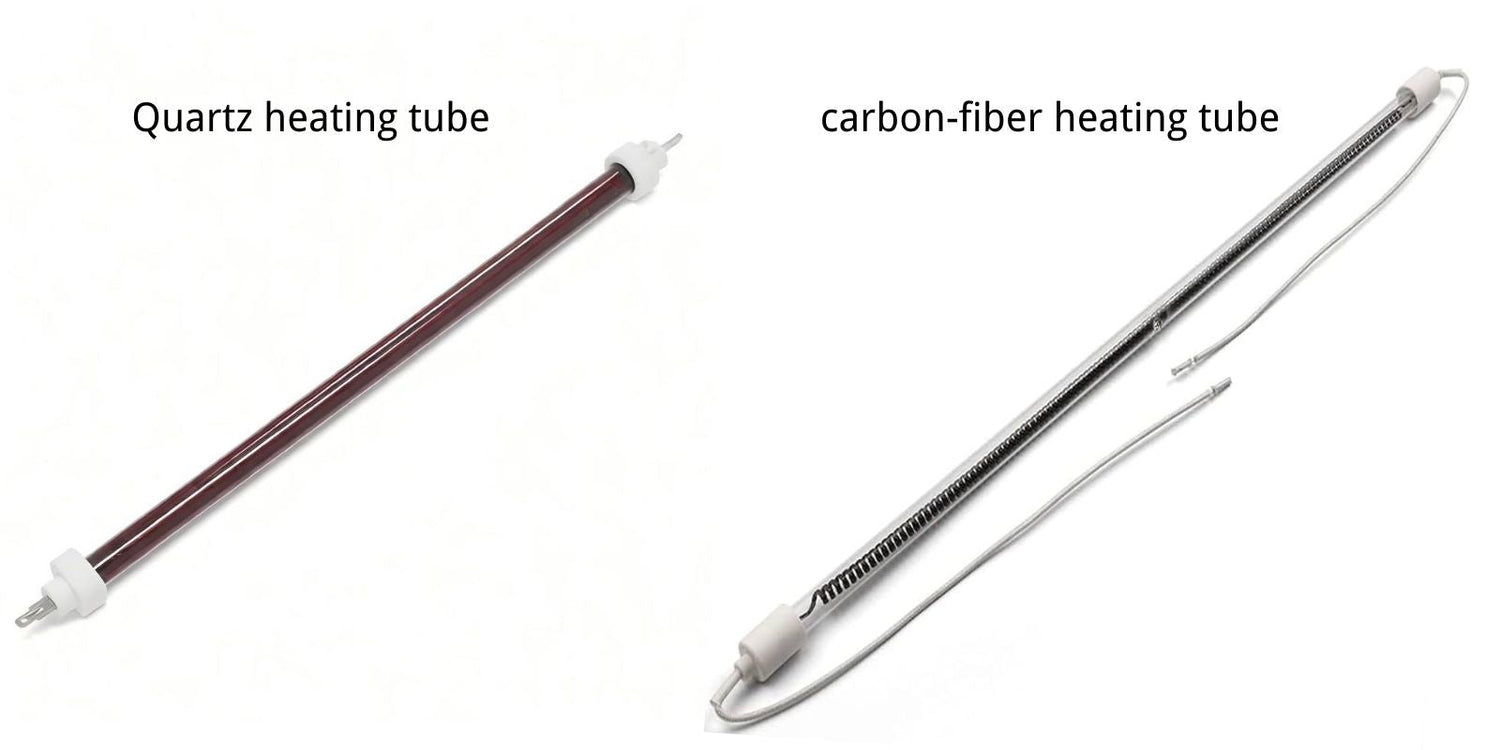

Quartz Heating Tubes

- A quartz tube encloses a resistive heating filament (often tungsten or similar alloy). As electric current passes, the filament heats up and radiates infrared energy through the quartz glass.

- The quartz tube allows transmission of infrared radiation (various wavelengths depending on design), which then heats the oven’s interior or objects inside via radiation and some convection.

Carbon-Fiber Heating Tubes

- Inside a tube (often evacuated or filled appropriately), a carbon-fiber filament acts as the heating body. When energized, the carbon fiber emits infrared (especially far-infrared) radiation.

Carbon-fiber heaters are sometimes referred to as “pure black-body” heating elements, with high electro-thermal conversion efficiency and efficient infrared radiation, often delivering gentler radiant heat.

Advantages & Tradeoffs — Carbon-Fiber vs Quartz

Below is a comparison of key performance factors.

| Factor | Carbon-Fiber Heating Tubes | Quartz Heating Tubes |

|---|

| Energy Efficiency | High — carbon fiber converts electricity to heat with > 95% efficiency. Reportedly can save ~30% energy compared to traditional resistive elements. | Moderate — effective but part of energy may be lost via convection, and radiant efficiency lower than optimized carbon-fiber systems. |

| Heating / Heat Transfer | Infrared (especially far-IR) — gives uniform radiant heat; gentle, efficient warming. | Rapid radiant heating plus some convection; good for quick heating or where direct radiant + ambient heat is needed. |

| Response Time | Moderate to fast — good efficiency, stable output. | Fast — quartz lamps often heat up quickly, making them suitable for rapid preheat or quick-start ovens. |

| Lifespan / Durability | Typically longer — many sources indicate 5,000–8,000 hours service life. | Generally shorter — many quartz tubes rated around 2,000–3,000 hours under standard conditions. |

| Heat Uniformity & Stability | Strong — carbon-fiber tends to provide stable, evenly radiated far-infrared heat; less “hot-spot” risk. | Good — but heating may be less uniform compared to far-IR radiation, can have more air-temperature fluctuation or edge variations. |

| Fragility / Handling | More robust under thermal cycling (less risk of burnout/oxidation) when properly sealed. | Quartz glass is more fragile — risk of breakage during transport or under mechanical/thermal shock. |

| Cost / Complexity | Slightly higher upfront cost; manufacturing requires vacuum sealing etc. | Lower initial cost; simpler to produce and package. |

Which One Is Better — Depends on the Oven / Application

Choose Carbon-Fiber Heating Tubes when:

- You aim for energy efficiency and long-term operating cost savings.

- You need uniform infrared heating — e.g. for baking, gentle cooking, maintaining stable inner-oven temperature.

- Durability and long lifespan are priorities (e.g. commercial ovens, heavy-duty use, frequent cycling).

- You design premium or high-end ovens where performance, reliability, and energy efficiency matter to end users or OEM clients.

- You want to offer an OEM/ODM solution that stands out from basic resistive/quartz heating — emphasizing quality and advanced material/technology.

Choose Quartz Heating Tubes when:

- You prioritize lower initial cost and simpler manufacturing.

- You need fast heat-up — e.g. ovens that preheat quickly, broiler or grill functions requiring high instantaneous heat.

- The oven is basic / budget-level, where cost-effectiveness outweighs long-term efficiency.

The application does not demand long operating hours or heavy duty cycles (e.g. small kitchen appliances, occasional-use ovens).

Tradeoffs & Practical Considerations

- Although carbon-fiber heating tubes have a longer nominal lifespan, they require proper sealing and manufacturing standards (vacuum sealing, quality of carbon filament, insulation) to realize that reliability. Lower-quality carbon tubes may underperform.

- Quartz tubes, while cheaper, are more fragile (glass envelope); mechanical shock or rapid thermal cycling may shorten actual lifespan.

- For ovens with frequent switching on/off, high thermal load, or quick preheat cycles, quartz might degrade faster. Carbon-fiber performs better under heavy cycle workloads.

- Heating behavior differs: carbon-fiber’s far-infrared radiant heat may yield different cooking characteristics (slower ambient air heating, more surface radiation) compared to quartz + convection; oven design (air circulation, insulation, door sealing) must consider that.

Conclusion: No Universal “Best” — Choose Based on Use Case

- If you design premium, durable, energy-efficient ovens for frequent/heavy use, carbon-fiber heating tubes are typically the better choice thanks to higher efficiency, longer life, uniform heating, and lower total cost of ownership.

- If you design cost-sensitive, entry-level ovens or appliances with occasional use and where rapid preheat or grill functions matter more than efficiency, quartz heating tubes remain a valid, budget-friendly option.

For a company like Sundear Group, offering carbon-fiber heating elements positions you strongly toward high-performance, energy-efficient, and durable oven solutions — a competitive advantage for OEM/ODM clients targeting premium appliance markets.