As kitchen appliances evolve, heating elements — the heart of ovens, cookers, and other cooking devices — are seeing important innovations in 2025. Here are the major trends shaping the industry, and how manufacturers and OEMs (like Sundear Group) should adapt.

1. Smart & “Connected” Heating Elements — Integration with IoT, Sensors & Controls

- The broader heating-element market is increasingly adopting smart control and IoT integration: sensors for temperature feedback, usage tracking, predictive maintenance, and real-time monitoring.

- For kitchen appliances, this can mean ovens that monitor heating-tube performance, adjust heat dynamically for better cooking consistency, or alert users to maintenance needs — adding value beyond just “on/off” heating.

- As consumers expect more “smart” kitchens, embedding heating-element intelligence helps appliance makers stand out and meet modern demands.

Implication for Sundear: Offering heating elements pre-wired or sensor-ready (temperature, usage lifetime, safety cutoffs) could differentiate your OEM/ODM offering.

2. Advanced Materials & Higher-Performance Heating Elements

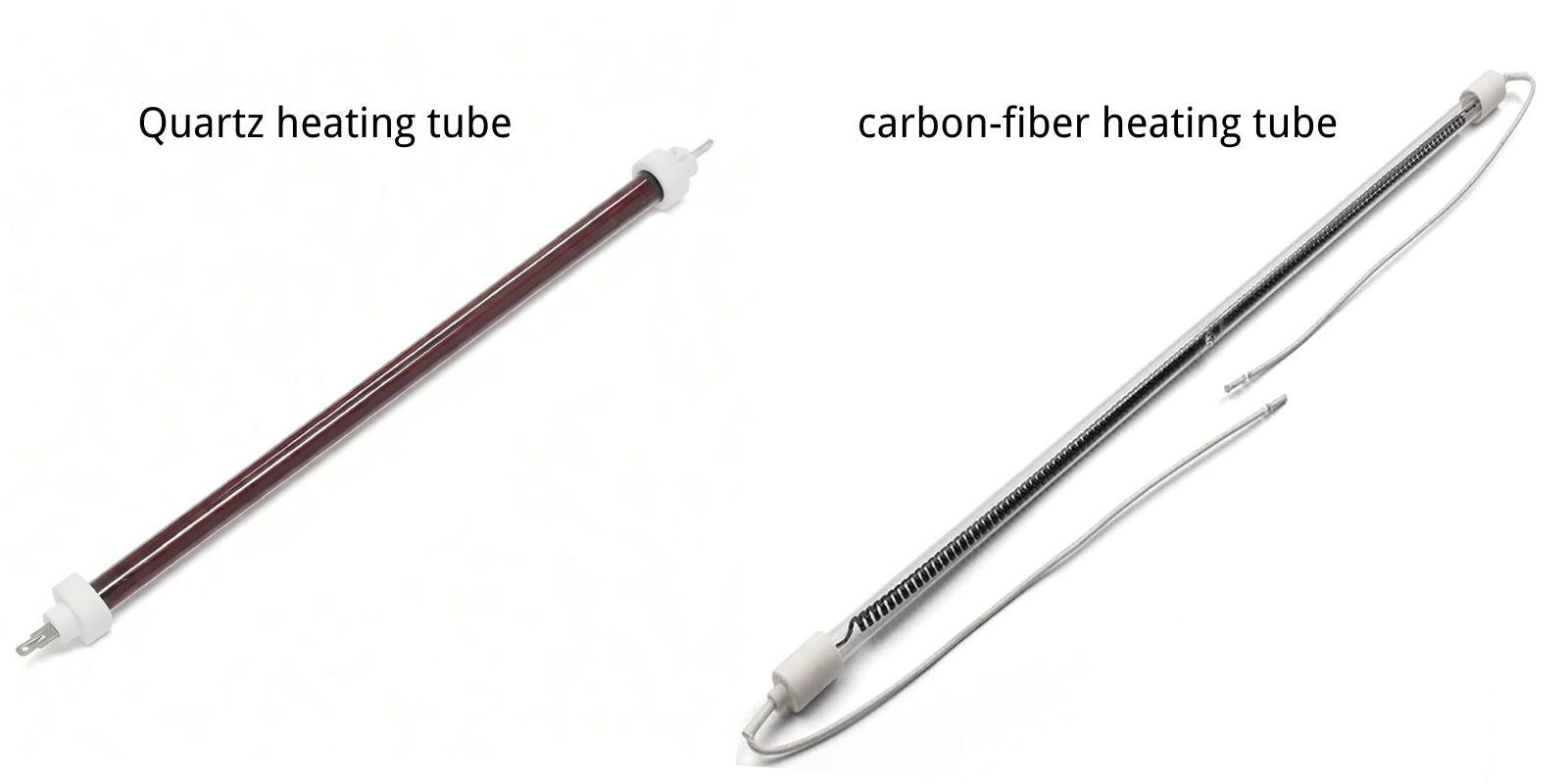

- The heating-element industry report for 2025 highlights a shift toward new materials — advanced ceramics, silicon-carbide, composite alloys — in addition to traditional resistive heaters.

- Such materials bring higher thermal stability, longer lifespan under repeated heating cycles, and better resistance to oxidation or thermal fatigue — crucial for heavy-use ovens or commercial kitchen equipment.

- There is also growing demand for custom, non-standard heater shapes and configurations (e.g. flexible, printed heaters, thin-profile elements) to allow more design freedom in compact or specialized kitchen appliances.

Implication for Sundear: Expanding R&D into advanced-sheath materials, ceramic-based elements, or custom-shaped heaters can position Sundear as a high-performance, next-gen supplier.

3. Energy Efficiency & Eco-Friendly / Sustainable Heating

- With global attention on energy consumption and environmental impact, heating-element producers are focusing on improving thermal efficiency, reducing material waste, and enhancing durability to lower replacement frequency — all reducing lifecycle environmental footprint.

- For household ovens and commercial appliances, more efficient heating tubes can mean lower power consumption, faster heating, and less heat loss — a selling point for both end users and OEMs aiming to meet energy standards.

Implication for Sundear: Emphasizing energy-efficient designs (e.g. low watt-density carbon-fiber heaters, improved insulation, optimized heat distribution) will appeal to eco-conscious markets and regulation-sensitive regions.

4. Customization & OEM/ODM-Oriented Solutions

- The industry is seeing growing demand for customizable heaters — because appliance designs vary widely: from compact toaster ovens to large commercial ovens, from convection ovens to infrared broilers.

- Custom heating elements — tailored size, shape, power rating, thermal behavior — are more attractive than “one-size-fits-all” standard products.

Implication for Sundear: As an OEM/ODM supplier, you are well placed to leverage this trend — offering bespoke heater designs adapted to each appliance’s geometry, cooking profile, and power/efficiency requirements.

5. Smart Kitchen & Appliance-Level Trends Raising Demand for Advanced Heating

- According to recent 2025 kitchen-appliance outlook guides, kitchens are moving toward smart, integrated appliances, combining multiple functions (baking, grilling, air fry, convection, rapid preheat, etc.) — which increases demand for flexible and high-performance heating systems.

- Modern ranges and ovens emphasize fast preheat, multi-mode cooking (convection, broil, air-cook, grill), and responsive temperature control — all relying on heating elements that can perform reliably under varied thermal cycles.

Implication for Sundear: Supplying versatile, durable heating elements optimized for multi-function ovens (combination ovens, air-fry + bake + grill) will meet rising market requirements.

6. Emphasis on Quality, Durability & Lifecycle Performance — for Both Home & Commercial Use

- As heating elements are subjected to more frequent cycles (especially in commercial kitchens), manufacturers emphasize durable designs, resistance to thermal stress, and long operational lifespan.

- Advanced materials, better insulation, and design optimization help mitigate common failure modes (oxidation, burnout, uneven heating, component fatigue).

Implication for Sundear: Promoting long lifespan, reliability testing, material traceability, and quality assurance is critical — especially when supplying to OEMs targeting demanding markets (commercial baking, pro-style ovens, heavy domestic use).

7. Hybrid Heater Concepts & New Heating Technologies (Beyond Traditional Resistance)

- While traditional resistive heating remains dominant, there is growing interest in hybrid or alternative heating technologies, including advanced ceramics, infrared radiative heaters, and possibly newer materials that combine resistive and radiative heating for optimized cooking performance.

- These offer faster heat-up, more even radiation, lower energy use, which align with modern consumer expectations for speed, efficiency, and cooking versatility.

Implication for Sundear: Investing in R&D and pilot production of hybrid or alternative heating elements (e.g., ceramic-based, radiative infrared + resistive hybrids) could place Sundear at the cutting edge — and appeal to forward-looking appliance makers.

What This Means for Sundear Group — Strategic Takeaways

- Highlight customization capabilities — design heaters specifically for smart, multi-function ovens, compact appliances, or commercial units.

- Invest in advanced materials and R&D to support high-efficiency, durable, next-gen heating elements (ceramics, composites, radiative designs).

- Position Sundear as a “solutions partner,” not just a component supplier — offer design consultation, smart-sensor integration, performance testing, and OEM support.

- Promote energy efficiency and sustainability — key selling points for consumers and regulators in 2025.

- Anticipate demand from smart kitchen and multi-function appliance market — develop heating elements that support rapid heating, precise control, and varied cooking modes.