Daily capacity: 100,000pcs

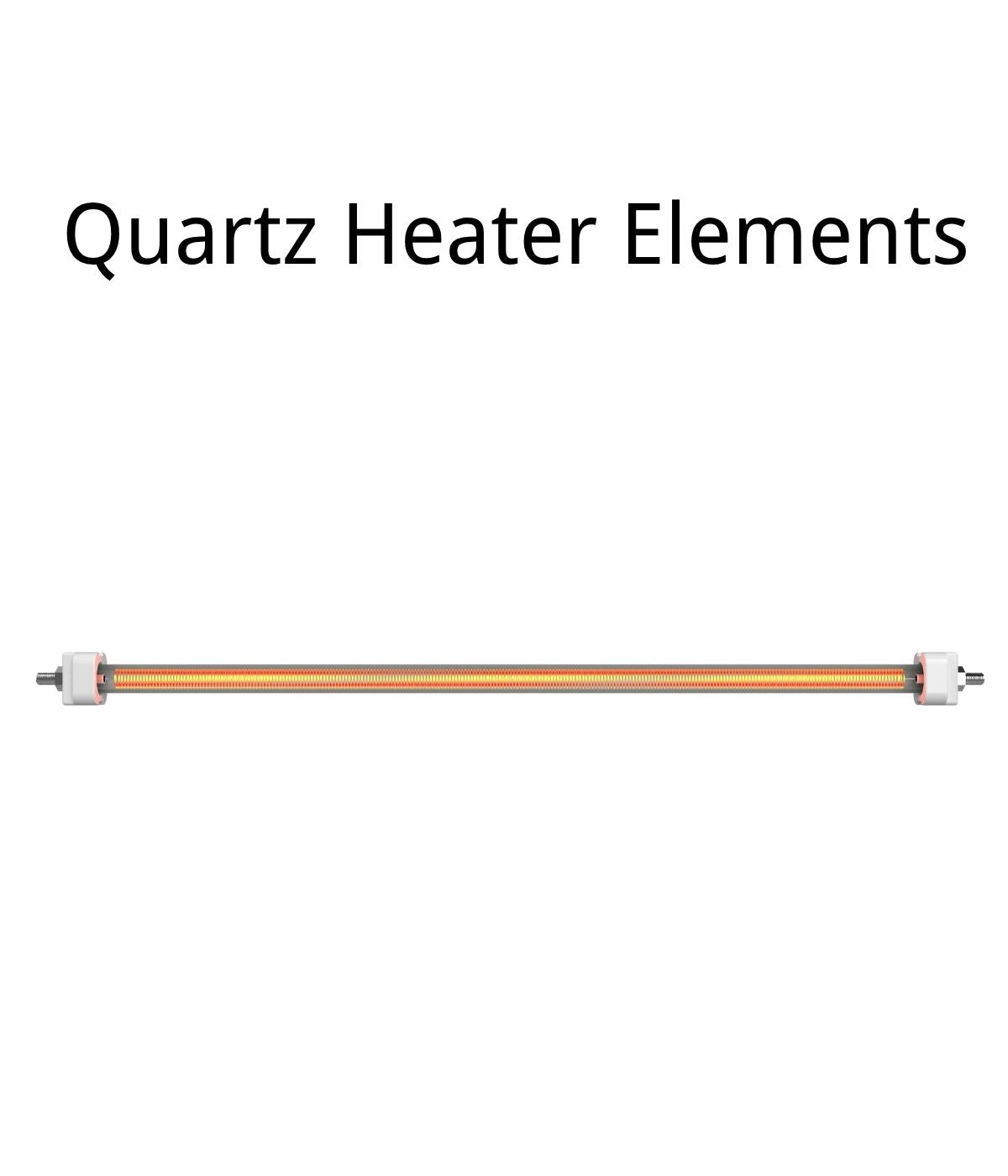

Quartz Heating Elements

SUNDEAR quartz heating tubes are designed for fast, energy-efficient, and reliable infrared heating in industrial, commercial, and residential applications.

Manufactured with high-purity quartz glass and precision resistance wire, our infrared quartz heating elements deliver instant heat, stable output, and long service life.

Daily capacity: 12,000kgs

Quartz Glass Tube

SUNDEAR Quartz Glass Tubes are engineered for superior performance, providing unmatched thermal stability and high resistance in a wide range of applications.

Made from premium-grade quartz glass, our tubes offer exceptional clarity, durability, and high-temperature resistance, making them ideal for industrial, commercial, and residential heating solutions.

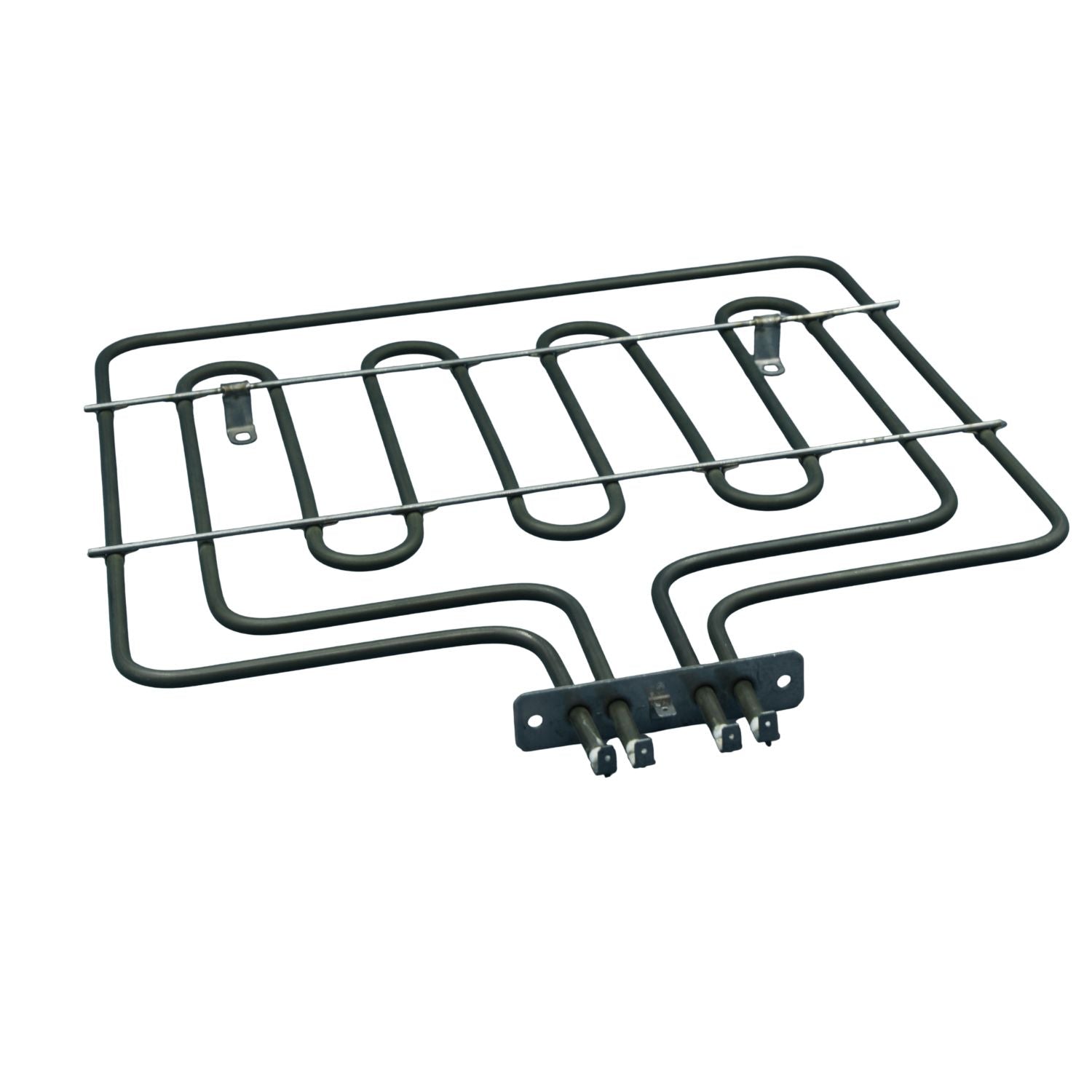

Built for Every Cooking Application

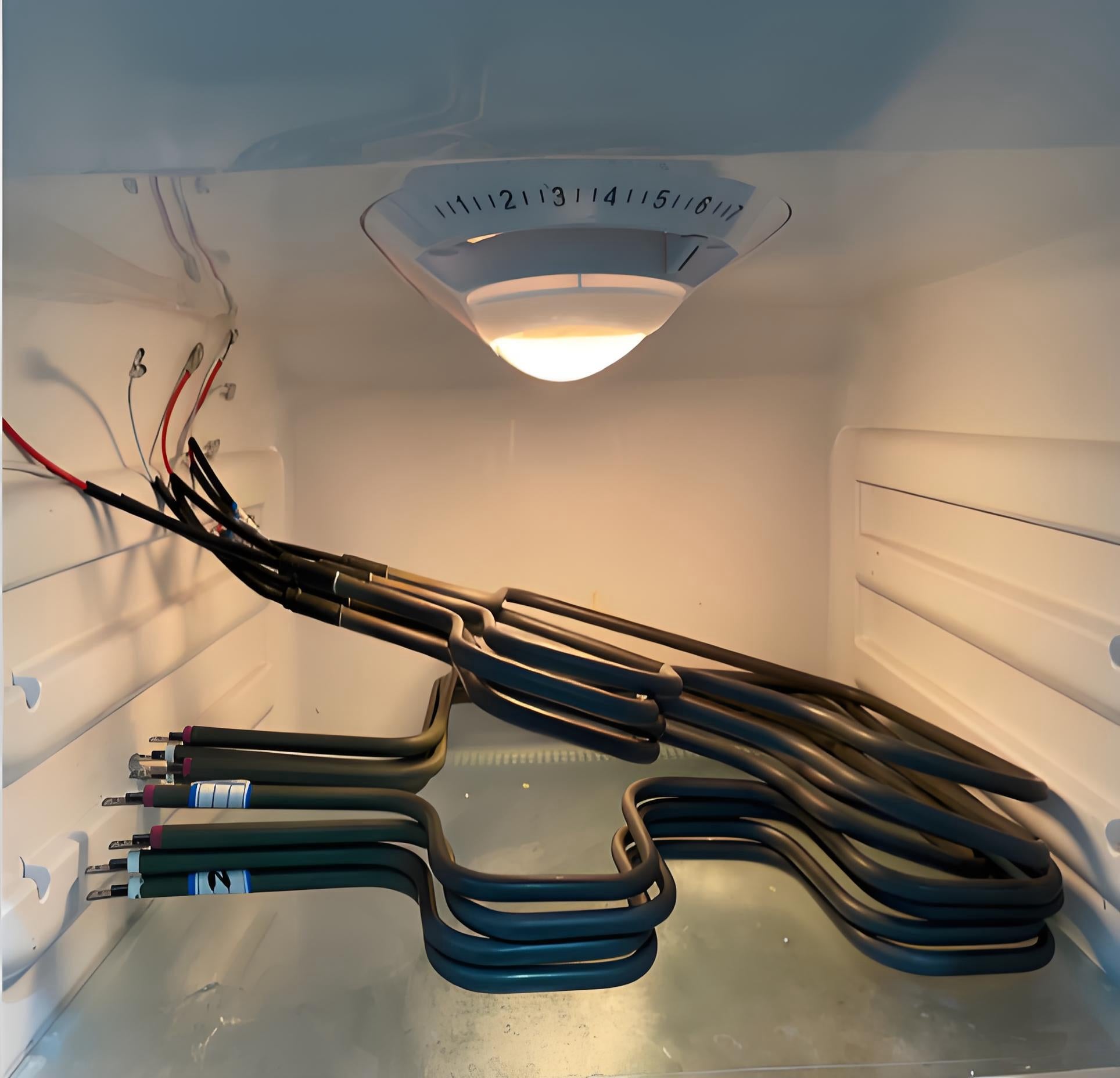

Tubular Heating Elements

SUNDEAR Tubular Heating Elements are designed to provide reliable and efficient heat for a wide range of applications, including industrial, commercial, and residential heating systems.

Known for their durability, high performance, and energy efficiency, our tubular heating elements are perfect for use in boilers, water heaters, ovens, industrial equipment, and more.

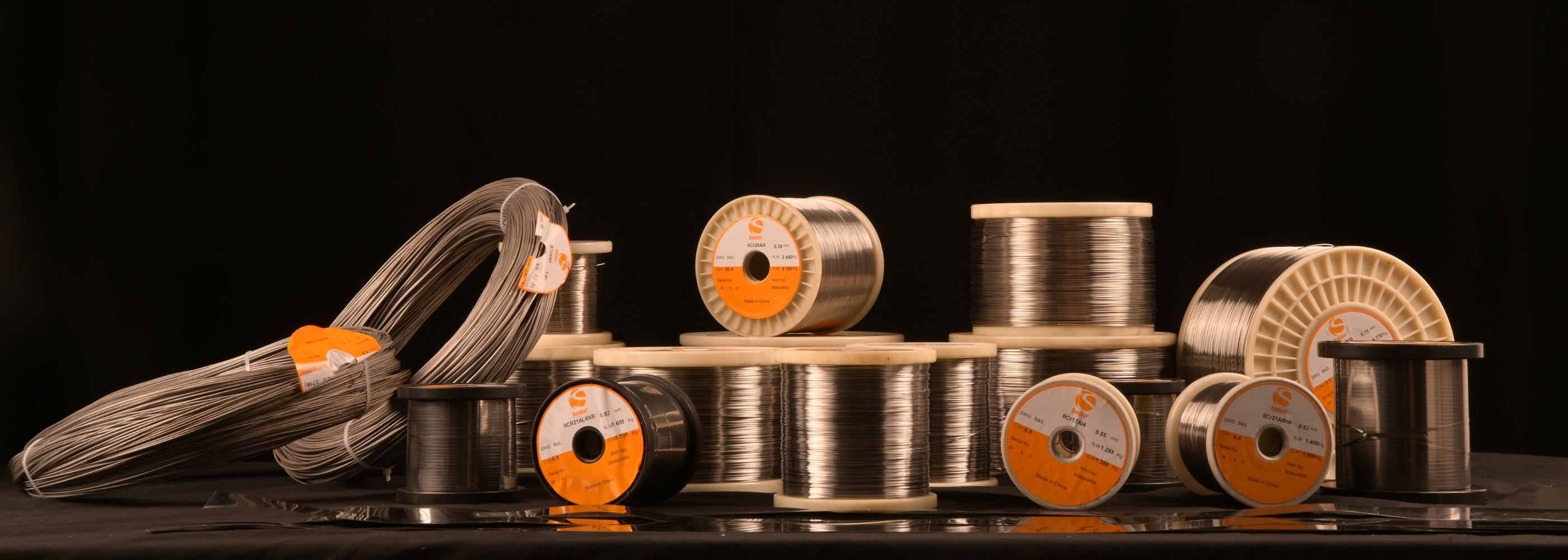

Resistance Alloy Wires and Ribbons

SUNDEAR Resistance Alloy Wire and Ribbons are engineered to provide exceptional electrical resistance and thermal stability across a broad range of industrial applications.

Manufactured from premium-quality resistance alloys, our wires and ribbons are trusted by OEMs for use in heating elements, industrial furnaces, automotive components, and many other demanding environments.

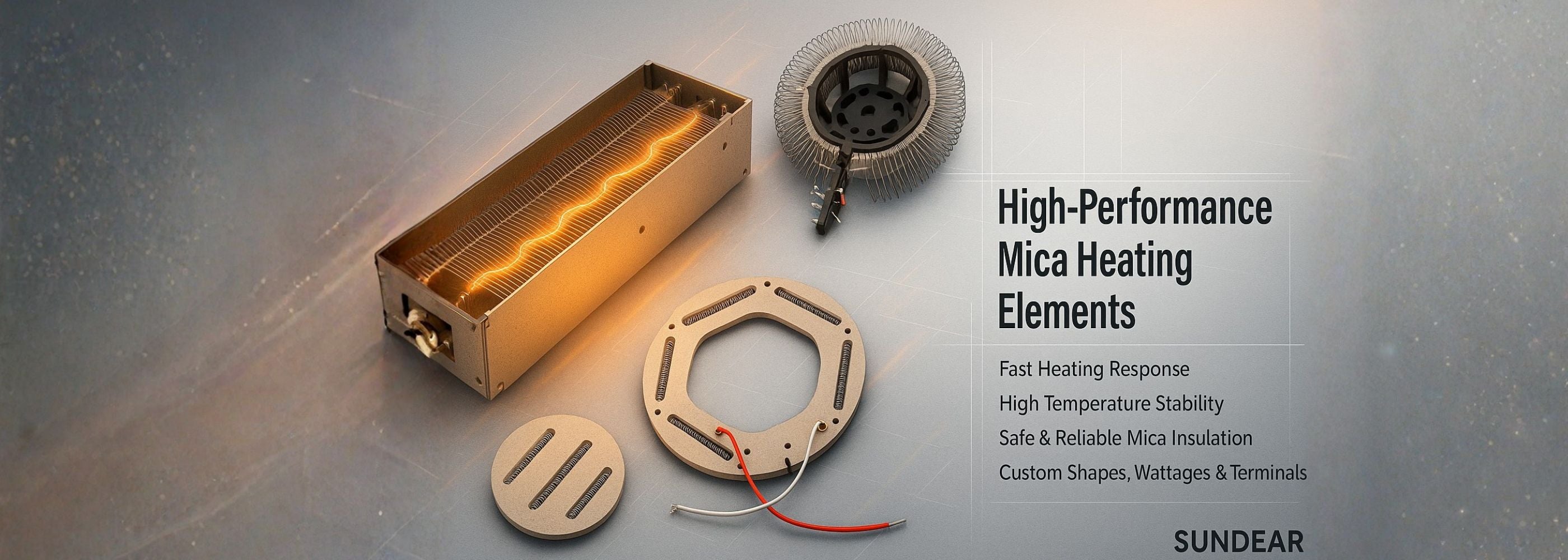

MICA Heating Elements

SUNDEAR Mica Heating Elements are engineered to provide fast, reliable, and energy-efficient heating for a wide range of applications.

Constructed using high-quality mica insulation and resistance wire, our mica heating elements are ideal for use in industrial, commercial, and residential heating systems, delivering uniform heat distribution and long-lasting performance.

Introducing Xinda — China’s Leading Heating Elements Manufacturer

For more than 30 years, Sundear has been at the forefront of heating-element innovation, supplying high-performance heating solutions to appliance manufacturers around the world.

From oven heater elements to electric heater elements, , hair-dryer heaters, and custom heating systems for small home appliances and resistance heating wires, we engineer reliable, efficient heat for every application.

As one of China’s largest and most experienced heating-element producers, Sundear combines advanced production technology with strict quality control to deliver stable performance, long service life, and global safety compliance.

Our expertise spans the full spectrum of heating technologies — tubular heaters, quartz heaters, quartz heating tube, carbon and halogen heating lamp, mica heaters, and resistance heating wires — enabling us to support OEM and ODM requirements across multiple industries, including kitchen appliances, personal-care devices, commercial equipment, and home-comfort products.

Backed by automated production, strong R&D capability, and a commitment to innovation, Sundear continues to expand its footprint as a trusted global partner to appliance brands seeking dependable heating solutions.

Heat Innovation for a World of Appliances — this is the Sundear promise.

Factory Area

40,000㎡

Employees

800+

Established

1988

Production Capability

200 K pcs / day

Quality Testing Lab

Equipments

Life Time Vertifying

3000H+

Blog & News

Oven Heating Elements: Top 10 Manufacturers of 2025

Selecting a manufacturer from this list ensures that your appliances are equipped with the most reliable oven heating elements available in 2025. From the innovation of Sundear to the German precis...

Sundear ensures the safety and reliability of its heating tubes by subjecting them to a rigorous Low-Temperature & High-Humidity Environmental Test, simulating extreme conditions like condensat...

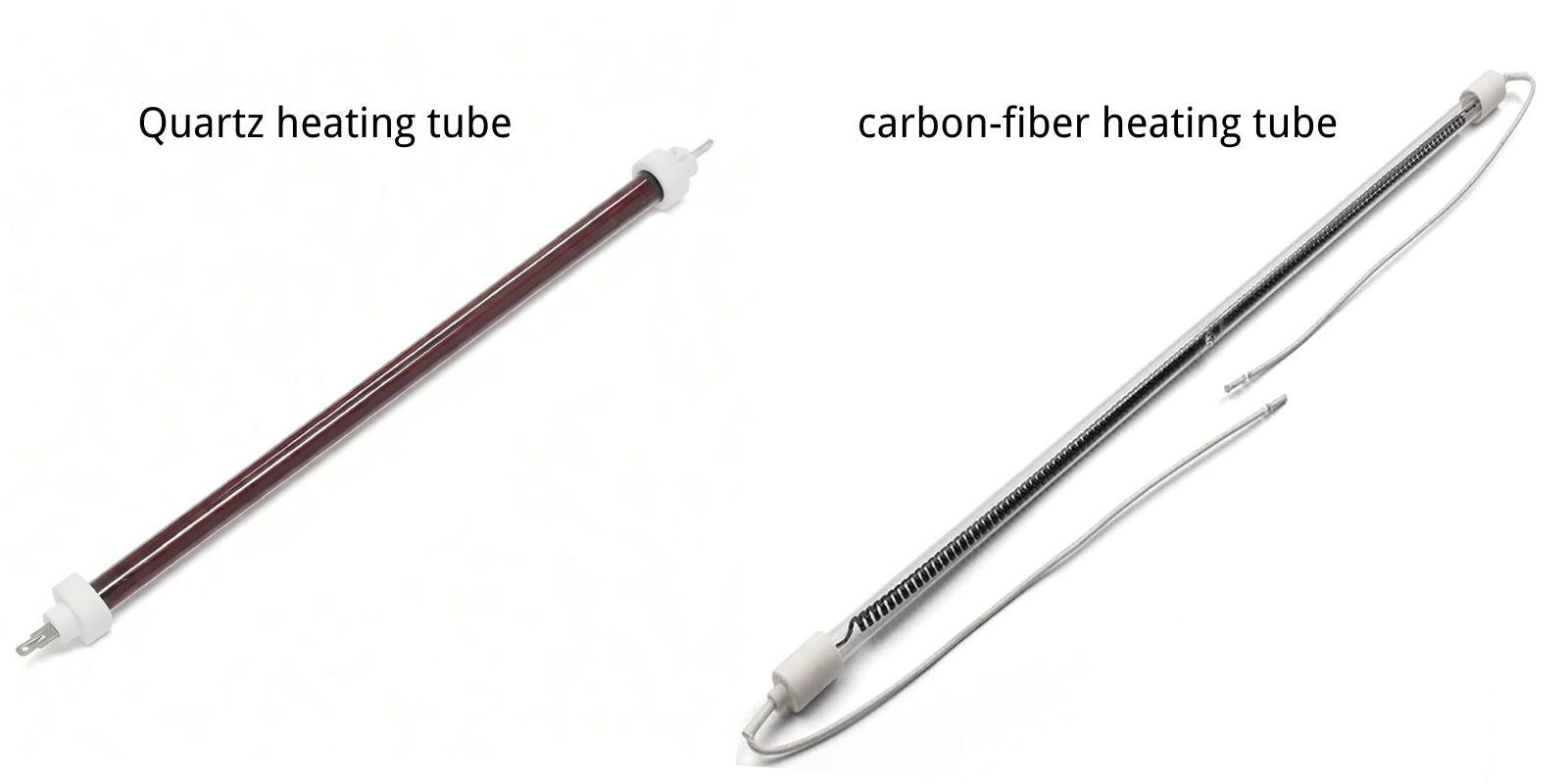

Carbon-Fiber Heating Tubes vs Quartz Heating Tubes: Which Is Better for Ovens?

For ovens, carbon-fiber heating tubes are superior for energy efficiency, durability, and uniform heating, justifying a higher cost for premium applications. Conversely, quartz tubes are the choice...

Top 2025 Trends in Heating Elements for Kitchen Appliances

The 2025 heating element market requires a shift toward smart, highly customizable, and energy-efficient elements using advanced materials. Sundear must adapt by investing in next-gen, durable tech...